|

Fenghua Xinling Pneumatic Engineering Co.,Ltd.

|

China Pneumatic Air Lubricators

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Our FL AL2000-02 pneumatic air lubricator is without bowl guard. We've been supplying this product to USA and some EU countries for more than 10 years

Product name: Pneumatic Air Lubricator

Model No.: AL2000-02

----- AL2000-02 Lubricators

Symbol of China Air Lubricators:

Symbol of China Air Lubricators:

Specification of High Quality Lubricators:

Product Features of FL Air Lubricators:

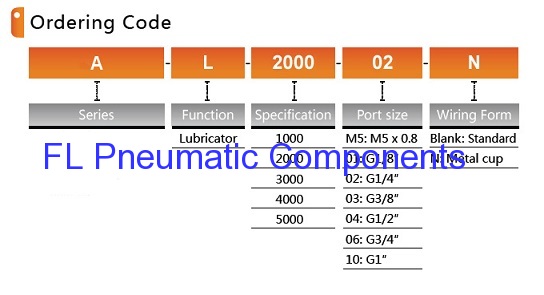

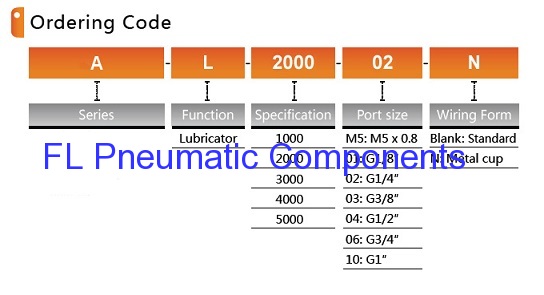

Ordering Code of AL2000-02 Air lubricators:

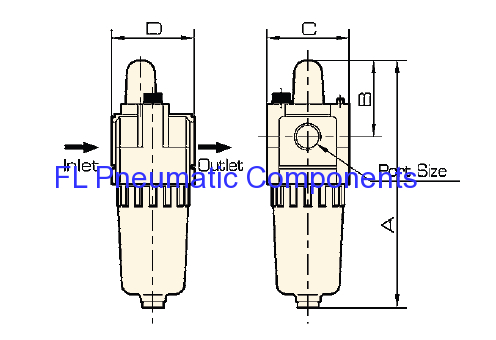

Dimension of AL Series Lubricators:

| Model | AL1000-M5 | AL2000-01 | AL2000-02 | AL3000-02 | AL3000-03 | AL4000-03 | AL4000-04 | AL4000-06 | AL5000-06 | AL5000-10 |

| Fluid | Air | |||||||||

| Proof Pressure | 1.5MPa(217psi) | |||||||||

| Max. Operating Pressure | 1.0MPa(145psi) | |||||||||

| Ambient and Fluid Temperature | 5--60℃ | |||||||||

| Recommended Lubricant | Class 1 Turbine Oil(ISO VG32) | |||||||||

| Bowl Guard | Not Available | Available | ||||||||

| Regulator Construction | Relieving Type | |||||||||

| Min. Dripping Flow Rate | 4 | 15 | 30 | 40 | 40 | 50 | 50 | 190 | ||

| Rated Flow | 95 | 800 | 1700 | 5000 | 6300 | 7000 | ||||

| Port size | M5 | G1/8 | G1/4 | G3/8 | G1/2 | G3/4 | G1 | |||

| Oil capacity | 7 | 25 | 50 | 130 | ||||||

| Weight | 70g | 220g | 300g | 560g | 580g | 1080g | ||||

Product Features of FL Air Lubricators:

It is same style as SMC.

Regulators insure operation in steady pressure, decrease damage of valve and cylinder.

Filters remove moisture from compressed air, ensure it is clean and dry.

Lubricators are good for moving components, extend their working life.

Ordering Code of AL2000-02 Air lubricators:

Dimension of AL Series Lubricators:

| Model | Bore | A | B | C | D |

| AL1000 | M5 | 81.5 | 25.5 | 25 | - |

| AL2000 | G1/8--G1/4 | 122 | 38 | 40 | 40 |

| AL3000 | G1/4--G3/8 | 142 | 38 | 53 | 53 |

| AL4000 | G3/8--G1/2 | 177 | 41 | 70 | 70 |

| AL4000-06 | G3/4 | 177 | 39 | 70 | 70 |

| AL5000 | G3/4--G1 | 254 | 45 | 90 | 90 |

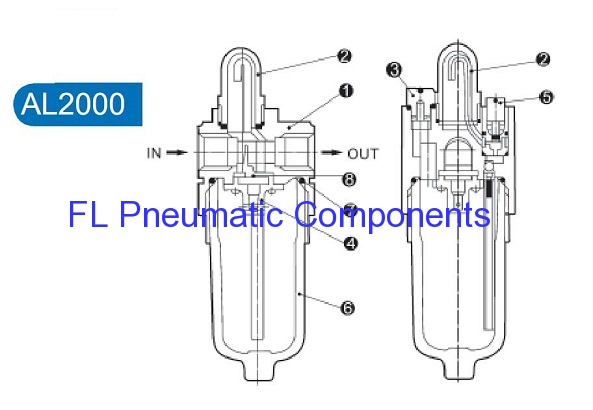

Structure of FL Good Quality Lubricators:

| NO. | Description | Material | ||

| AL1000 | AL2000-AL4000 | AL5000 | ||

| 1 | Body | Zinc Die-Cast | Aluminum Alloy Die-Cast | |

| 2 | Sight Dome Assembly | Polycarbonate,Nylon | ||

| 3 | Oil Feed Plug | POM | ||

| 4 | Deflector Gate | POM | ||

| 5 | Oil Adjusting Handle | POM | ||

| 6 | Bowl Guard | Polycarbonate(Cold Rollded Steel), PC K1300(Cold Rolled Steel) | ||

| 7 | O-Ring | NBR | ||

| 8 | Retainer | POM | ||

| 9 | O-Ring | NBR | ||

| 10 | Middle Part | Aluminum Alloy Die-Cast | ||

Air lubricators have been an important part ofpneumatic systems for decades. Lubrication helps reduce friction betweensliding surfaces to not only improve efficiency and increase cyclingspeed of a component, but reduces wear, which ultimately means longercomponent life and less maintenance. Moreover, in a pneumatic system,lubrication can reduce both internal and external leakage around valvespools, cylinder rods and pistons, and air motor and rotary actuatorvanes, rotors, and housings, as well as other components.

This goes forconventional pneumatic components as well as those thatcan operate with non-lubricated air. Ultimately, the total savings fromusing lubricated air can exceed the cost of installing and maintainingthe lubricators.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

.jpg)

.jpg)

.jpg)

.jpg)