|

Fenghua Xinling Pneumatic Engineering Co.,Ltd.

|

High Quality Air Cylinder

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

SC Tie rod cylinder is made of aluminum and with carbon steel piston rod. We are professional manufacturer of tie rod pneumatic air cylinders in China

Pneumatic cylinders vary in appearance, size and function, they generally fall into one of the specific categories below:

1. Single acting cylinder

2. Double acting cylinders

3. Rodless cylinders

However there are also numerous other types of pneumatic cylinders available, many of which are designed to fulfill specific and specialized functions.

* Through rod air cylinders: piston rod extends through both sides of the cylinder, allowing for equal forces and speeds on either side.

* Cushion end air cylinders: cylinders with regulated air exhaust to avoid impacts between the piston rod and the cylinder end cover.

* Rotary air cylinders: actuators that use air to impart a rotary motion.

* Rodless air cylinders: These have no piston rod. They are actuators that use a mechanical or magnetic coupling to impart force, typically to a table or other body that moves along the length of the cylinder body, but does not extend beyond it.

* Tandem air cylinder: two cylinders are assembled in series in order to double the force output.

* Impact air cylinder: high velocity cylinders with specially designed end covers that withstand the impact of extending or retracting piston rods.

Product name: SC63X75 Air Cylinder

1. Single acting cylinder

2. Double acting cylinders

3. Rodless cylinders

However there are also numerous other types of pneumatic cylinders available, many of which are designed to fulfill specific and specialized functions.

* Through rod air cylinders: piston rod extends through both sides of the cylinder, allowing for equal forces and speeds on either side.

* Cushion end air cylinders: cylinders with regulated air exhaust to avoid impacts between the piston rod and the cylinder end cover.

* Rotary air cylinders: actuators that use air to impart a rotary motion.

* Rodless air cylinders: These have no piston rod. They are actuators that use a mechanical or magnetic coupling to impart force, typically to a table or other body that moves along the length of the cylinder body, but does not extend beyond it.

* Tandem air cylinder: two cylinders are assembled in series in order to double the force output.

* Impact air cylinder: high velocity cylinders with specially designed end covers that withstand the impact of extending or retracting piston rods.

Product name: SC63X75 Air Cylinder

Model Number: SC63X75

----- SC63X75 Pneumatic Cylinder

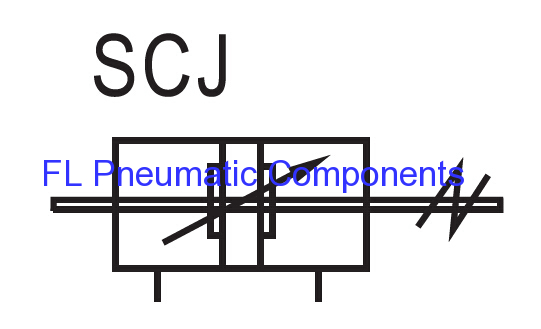

Symbol of China Pneumatic Air Cylinder:

Specification of FL Pneumatic Components-SC Series Air Cylinder:

Stroke of China Pneumatic Components-SC Series Pneumatic Cylinder:

Specification of FL Pneumatic Components-SC Series Air Cylinder:

| Bore | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 200 | 250 | 320 | |

| Operation Type | Double Acting | |||||||||||

| Working Medium | Air | |||||||||||

| Pressure Range | 0.05Mpa--0.85Mpa(7.3--123Psi) | |||||||||||

| Proof Pressure | 1.35MPa(217psi) | |||||||||||

| Working Temperature | 0--70℃ | |||||||||||

| Working Speed Range | 50--800 mm/s | |||||||||||

| Cushion | Adjustable Cushion | |||||||||||

| Adjustable Cushion Stroke | 20mm | 26mm | 45mm | 52mm | 66mm | |||||||

| Port Size | G1/8 | G1/4 | G3/8 | G1/2 | G3/4 | G1 | ||||||

| Mounting Accessories | SC | BASIC, FA, FB, CA, CB, LB, TC, TC-M | ||||||||||

| SCD,SCJ | FA, FB, CA, CB, LB, TC, TC-M | |||||||||||

Stroke of China Pneumatic Components-SC Series Pneumatic Cylinder:

| Bore | Standard Stroke | Max. Stroke | Allowable Stroke |

| 32 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 | 1000 | 2000 |

| 40 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 | 1200 | 2000 |

| 50 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1200 | 2000 |

| 63 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 80 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 100 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 125 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 160 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 200 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 250 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 320 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

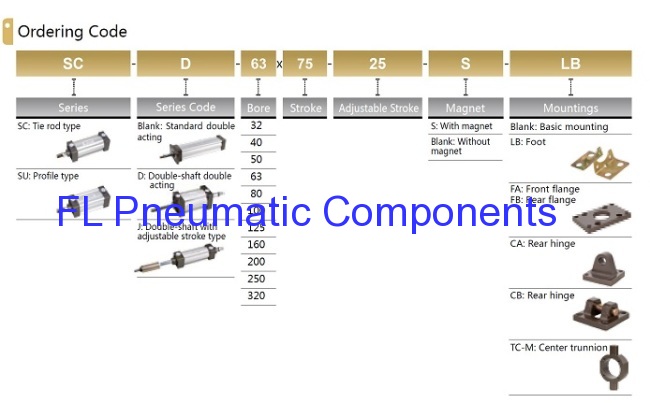

Ordering Code of FL Pneumatic Components-SC63X75 Series Air Cylinder:

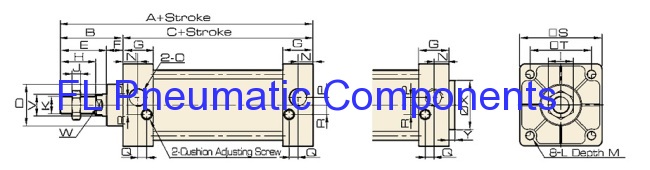

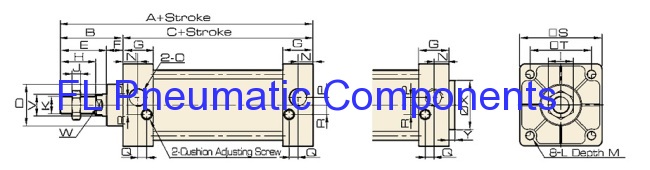

Dimension of FL Pneumatic Components-SC Series Air Cylinder:

| Bore/Symbol | A | A1 | A2 | B | C | D | E | F | G | H | I | J | K | L |

| 32 | 140 | 187 | 182 | 47 | 93 | 28 | 32 | 15 | 27.5 | 22 | 17 | 6 | M10 x 1.25 | M6 |

| 40 | 142 | 191 | 185 | 48 | 93 | 32 | 34 | 15 | 27.5 | 24 | 17 | 7 | M12 x 1.25 | M6 |

| 50 | 150 | 207 | 196 | 57 | 93 | 38 | 42 | 15 | 27.5 | 32 | 23 | 8 | M16 x 1.5 | M6 |

| 63 | 153 | 210 | 199 | 57 | 96 | 38 | 42 | 15 | 27.5 | 32 | 23 | 8 | M16 x 1.5 | M8 |

| 80 | 183 | 258 | 243 | 75 | 108 | 47 | 54 | 21 | 33 | 40 | 26 | 10 | M20 x 1.5 | M10 |

| 100 | 189 | 264 | 249 | 75 | 114 | 47 | 54 | 21 | 33 | 40 | 26 | 10 | M20 x 1.5 | M10 |

| 125 | 226 | / | / | 104 | 122 | 55 | 70 | 34 | 33 | 54 | 40 | 10 | M27 x 2 | M12 |

| 160 | 291 | / | / | 123 | 168 | 62 | 93 | 40 | 50 | 72 | 55 | 18 | M36 x 2 | M16 |

| 200 | 347 | / | / | 167 | 180 | 80 | 112 | 55 | 50 | 72 | 55 | 18 | M36 x 2 | M16 |

| 250 | 389 | / | / | 189 | 200 | 90 | 122 | 67 | 54 | 84 | 65 | 21 | M42 x 2 | M20 |

| 320 | 436 | / | / | 216 | 220 | 110 | 126 | 90 | 65 | 96 | 75 | 24 | M48 x 2 | M24 |

| Bore/Symbol | M | N | O | P | Q | R | S | T | V | W | Z | X | Y |

| 32 | 9.5 | 13.5 | G1/8 | 3.5 | 7.5 | 7 | 45 | 33 | 12 | 10 | 21 | / | / |

| 40 | 9.5 | 13.5 | G1/4 | 6 | 8.2 | 9 | 50 | 37 | 16 | 14 | 21 | / | / |

| 50 | 9.5 | 13.5 | G1/4 | 8.5 | 8.2 | 9 | 62 | 47 | 20 | 17 | 23 | / | / |

| 63 | 9.5 | 13.5 | G3/8 | 7 | 8.2 | 8.5 | 75 | 56 | 20 | 17 | 23 | / | / |

| 80 | 11.5 | 16.5 | G3/8 | 10 | 9.5 | 14 | 94 | 70 | 25 | 22 | 29 | / | / |

| 100 | 11.5 | 16.5 | G1/2 | 11 | 9.5 | 14 | 112 | 84 | 25 | 22 | 29 | / | / |

| 125 | 15.5 | 16.5 | G1/2 | 10 | 10 | 11 | 140 | 110 | 32 | 27 | / | / | / |

| 160 | 17.5 | 25 | G1/2 | / | / | / | 180 | 140 | 40 | 36 | / | / | / |

| 200 | 17.5 | 25 | G3/4 | / | / | / | 220 | 175 | 40 | 36 | / | / | / |

| 250 | 25 | 31 | G1 | 18.5 | 5 | 40 | 270 | 220 | 50 | 46 | / | 90 | 10 |

| 320 | 28 | 31 | G1 | 35 | 15 | 35 | 350 | 270 | 63 | 55 | / | 110 | 10 |

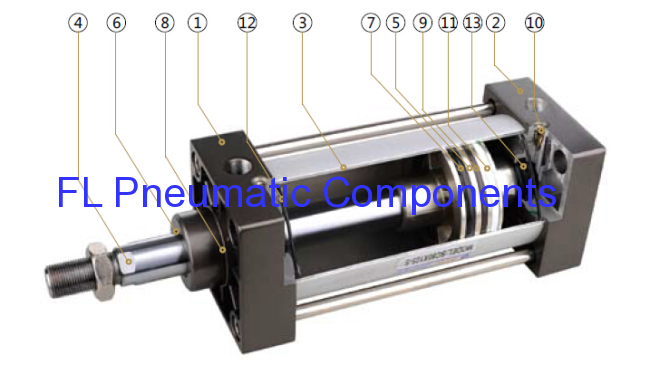

Structure of Pneumatic Components-SC Series Air Cylinder:

| No. | Name | Material |

| 1 | Front Cover | Painted Aluminum |

| 2 | Back Cover | Painted Aluminum |

| 3 | Barrel | Anodised Aluminum |

| 4 | Piston Rod | Chromed Carbon Steel |

| 5 | Piston | Aluminum |

| 6 | Piston Rod Seal | NBR |

| 7 | Piston Seal | NBR |

| 8 | Bearing | Non-lub Bearing |

| 9 | Magnet | Plastic |

| 10 | Cushion Screw | Brass |

| 11 | Anti-frintion Ring | PTFE |

| 12 | End Cap Seal | NBR |

| 13 | Cushion Seal | NBR |

Appllication of Air Cylinder: in various industries like equipments, machinery, moulding, ship building, CNC Machining.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

High Quality Bearing

High Quality Oil

High Quality Belts

High Quality Cameras

High Quality Faucet

High Quality Table

More>>

.jpg)

.jpg)

.jpg)

.jpg)